ASMPT

- TX_series

-

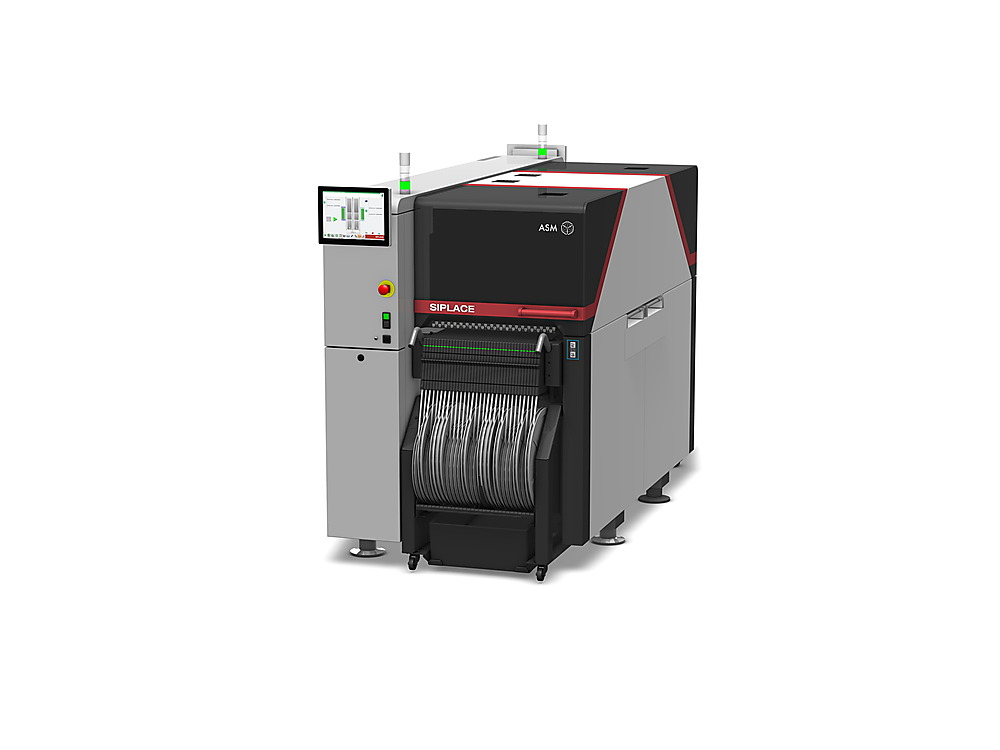

Machine type

SIPLACE TX2i

SIPLACE TX2

SIPLACE TX1

Placement speed

Up to 96,000 cph

Up to 85,500 cph

Up to 44,000 cph

Machine dimensions

(L × W × H)

1.00 m × 2.23 m × 1.45 m

1.00 m × 2.35 m × 1.45 m

Placement heads

SIPLACE SpeedStar (CP20P2), SIPLACE MultiStar (CPP), SIPLACE TwinStar (TH)

Component spectrum

0.12 mm x 0.12 mm to 200 mm × 125 mm**

PCB dimensions

(L × W)

50 mm × 45 mm to 550* × 260 mm (dual lane)

50 mm × 45 mm to 550* × 460 mm (single lane mode)

Component feeding

up to 80 × 8 mm tape feeders, JEDEC trays, Linear Dipping Unit, Glue Feeder

Typical power consumption

2.0 kW (with vacuum pump) 1.2 kW (without vacuum pump)

Compressed air consumption

120 Nl/min (with vacuum pump)

70 Nl/min (with vacuum pump)

Placement heads

SIPLACE SpeedStar (CP20P2)

SIPLACE MultiStar (CPP)

SIPLACE TwinStar (TH)

Component spectrum

0.12 mm x 0.12 mm

to 8.2 mm × 8.2 mm

01005 to 50 mm × 40 mm

0201 to 200 mm × 125 mm

Component height

4 mm*

15.5 mm

25 mm

Placement accuracy (3 σ)

25 µm

34 µm

22 µm

Maximum speed

48,000 cph

25,500 cph

5,500 cph

Placement force

0.5 N to 4.5 N

1.0 N to 15 N

1.0 N to 30 N

*2 mm on SIPLACE TX2i Performing professional maintenance in the scope and intervals recommended by ASM ensures

that your SIPLACE equipment will deliver the specified performance and accuracy across its entire life cycle.

Our various maintenance contracts make this job even easier for you.

- X_series

-

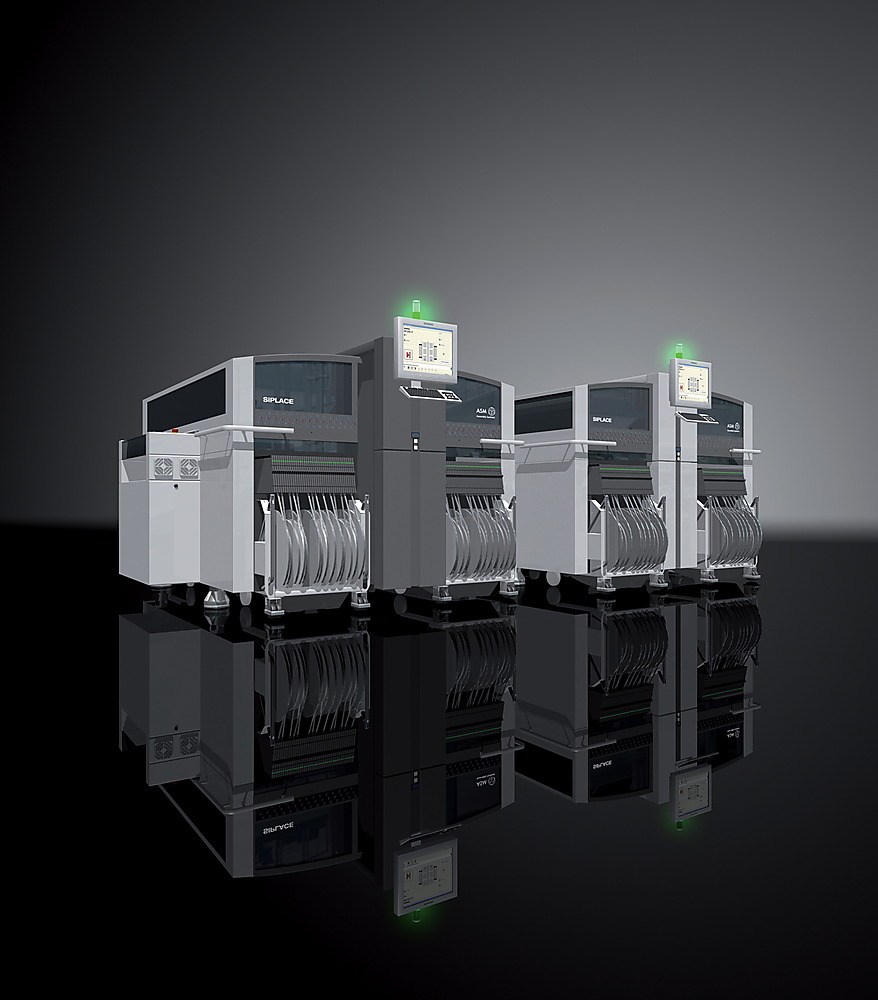

Machine

SIPLACE X4i

SIPLACE X4

SIPLACE X3

SIPLACE X2

Number of gantries

4

4

3

2

IPC-Performance

102,000 cph

81,000 cph

62.200 cph

43,400 cph

SIPLACE benchmark Performance

120,000 cph

90,000 cph

69.,500 cph

49,000 cph

Component spectrum

01005 to 27 x 27 mm²

01005 to 200 x 125 mm²

01005 – 200 x 125 mm²

01005 – 200 x 125 mm²

Head Types

SIPLACE 20-nozzle collect & place head

SIPLACE 12-nozzle collect & place head

SIPLACE 6-nozzle collect & place head

SIPLACE TwinHead

Placement accuracy

± 41 μm/3σ

± 41 μm/3σ

± 45 μm/3σ

± 22 μm/3σ

Angular accuracy

± 0.5 °/3σ

± 0,5 °/3σ

± 0,2 °/3σ

± 0,05 °/3σ

Conveyors types

Conveyor types

Flexible dual conveyor, single conveyor

Transport modes

Synchronous, asynchronous

PCB size

50 x 50 mm² – max. 685 x 610 mm²

PCB thickness

0.3 to 4.5 mm (ticker PCBs on request)

PCB weight

max. 3 kg

Component supply and feeder modules

Feeder slots

SIPLACE X changeover table: 160 8-mm X tape feeder modules

(148 tracks with SIPLACE X4i), SIPLACE HF changeover table: 180 tracks with 3 x 8mm S

Component supply

SIPLACE changeover table, SIPLACE Matrix Tray Changer (MTC)

X tape feeder modules, S tape feeder modules

Alternative feeder module types, Matrix trays, stick feeders, bulk case, application-specific OEM feeder modules

Quality ratings

Pickup rate

≥ 99.95 %**

Dpm rate

≤ 3 dpm*

Lightning levels

up to 6

* Performing professional maintenance in the scope and intervals recommended by ASM ensures that your SIPLACE equipment will deliver the

specified performance and accuracy across its entire life cycle. Our various maintenance contracts make this job even easier for you.

** According to evaluation criteria

- SX_series

-

- Placement Speed : Up to 96,000cph

(Machine size is only 1m × 2.23m)

- Wide components : Wide Spectrum

(0.12mm× 0.12mm ~ 200mm× 125mm)

- Accuracy : Placement Accuracy 25 µm(3 σ)

- Component feeding : Up to 80 × 8 mm tape feeders, JEDEC trays, Linear Dipping Unit, Glue Feeder

[이 게시물은 최고관리자님에 의해 2020-02-26 17:00:53 ASM에서 이동 됨]